The Rapunzel World

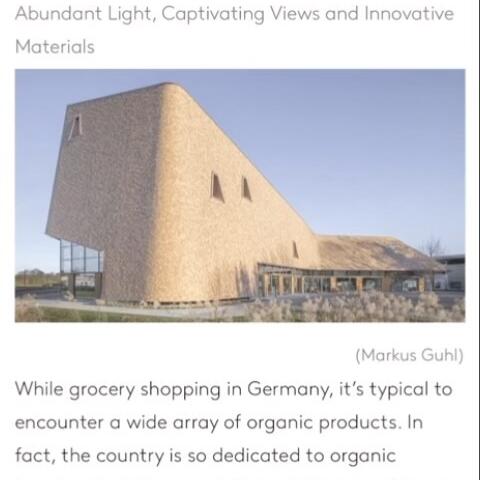

After three years of construction, a visitor center has emerged as a walk-in building sculpture on the premises of Rapunzel Naturkost GmbH in Legau.

The new visitor center is designed to be public and inviting and is intended to make Rapunzel's leitmotif "We make organic out of love" tangible for visitors. A house full of discoveries that invites guests to linger and participate with varied and emotional imparting of knowledge.

The address-forming building sculpture welcomes every visitor from afar through the northern high point - the Rapunzel Tower. The fairytale garden surrounds the house and extends to the roof. An open and invitingly accessible sculpture where at the end the crow's nest allows a view of the landscape.

The gesture is accompanied by the large, floating roof that spans everything and wraps itself around the visitor center like a band, but does not limit inside and outside views.

The new Rapunzel World makes the leitmotif of the company tangible with all senses. In the exhibition, visitors can learn interesting facts about cultivation, fair trade and production as well as sustainable living at interactive stations. The coffee roastery is designed in such a way that you can watch the roasting and processing, including the wonderful smell of the coffee. Rapunzel's braid in the form of a large, spiral wooden staircase connects all floors from the wine cellar to the exhibition and the roof terrace with its wonderful all-round view. In addition to the bakery and the organic market, there are many other rooms to discover for training courses, yoga and other activities. The playfully designed fairytale garden leads to the tropical house, where you can watch the coffee plants grow.

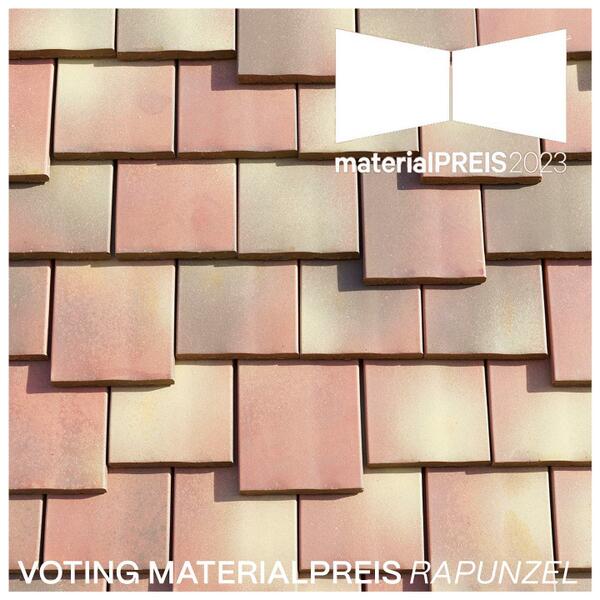

In addition to the obvious, the big, there are also the many small details, such as the copper downpipes of interlocking pots, or the playfully offset roof tiles, each with its own color nuance, which contribute to the special character of the Rapunzel world.

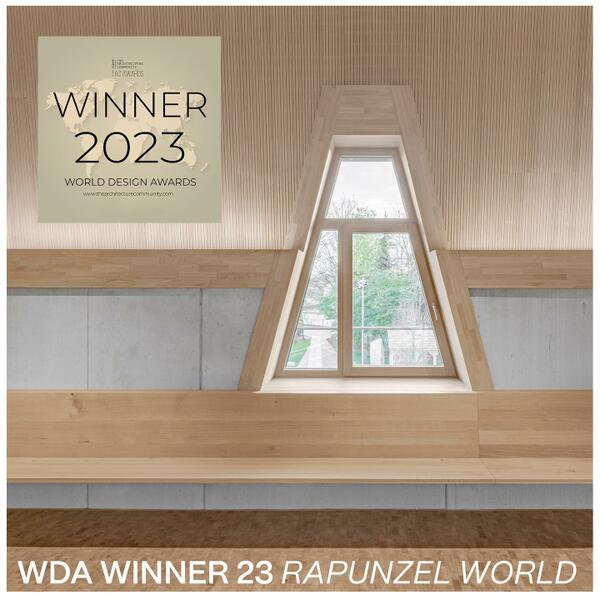

The wooden roof construction covered with tiles wraps itself around the three-part building structure like a continuous, floating band. The construction only reaches down to the ground in the tower area but otherwise stand out all around. The all-round glass façade on the ground floor remains as free and transparent as possible to allow insights and a large number of entrances and exits. All-round placed dormer windows ensure targeted views and natural lighting of the upper floors.

The organically curved form is created by three wings of the building stretching into the natural space, each of which contains different areas of use. The public area with the wooden spiral staircase sculpture is in the center of the Rapunzel World.

Ecology of the building and production

Observing the natural cycles of nature is a basis of organic farming. In the visitor center exhibition, visitors learn everything about the aspects of healthy nutrition, about its cultivation and processing.

We have also committed ourselves to this principle of an ecological circular economy in the architecture of the Rapunzel World. Natural and renewable building materials such as wood and clay were used and the building services were reduced to a necessary minimum.

No styrofoam was used for the insulation and the subfloor, but recycled foam glass gravel. All materials, colors and coatings are mineral and ecologically carefully selected.

Daylight is used in the visitor center and mechanical air conditioning is largely dispensed with. Here we used what nature provides us with as a microclimate on site to build a robust and therefore durable house that works with nature and not against nature.

Regional building materials

All the craft businesses that were involved in the construction of the Rapunzel World are located in the immediate vicinity of Legau. From local wood to the neighboring gravel works, local materials could be used in order to keep the ecological impact of long transport routes low. Only for the Rapunzel staircase and the finely engobed bricks, we had to resort to more distant partners, as the brick kilns in Switzerland still had old kilns that allowed a special type of engobe.

The building not only strengthens the region, but also helps the environment by avoiding emissions and resource consumption in transport.

A sustainable Rapunzel World

The position and arrangement of the rooms and the window openings were determined according to microclimatic aspects. The wide roof overhang ensures natural shading of the daylight-optimized rooms. The ventilation is natural. Only the areas of the roasting plant still have to be mechanically ventilated, since the heat loads here exceed normal levels. The building was connected to the already good local heating network and the solar power generation from Rapunzel. A life cycle assessment was drawn up and the energy involved, recyclability and transport were decisive factors in the choice of materials. Whenever possible, preference was given to renewable or recyclable building materials.

The spiral staircase made entirely of wood is the heart and connecting piece of the Rapunzel World. The approximately 12-tonne, 14.5-meter-high triple-spiral, self-supporting stringer staircase begins on the ground floor.

The primary load-bearing element of the spiral staircase is formed by the stair stringers made of curved laminated veneer lumber with a thickness of 15 cm and integrated into the balustrade. To reduce the susceptibility to vibration on the platforms, they are rigidly connected to the concrete structure via slotted sheets and consist of oak and spruce veneer layers with different orientations according to the structural requirements. The outer veneer layer consists of oak wood. It is arranged with the grain in the vertical direction and gives the staircase its specific appearance. The risers and steps (Kerto or BSH) were connected to the load-bearing stringers using an ingenious arrangement of fasteners in order to create the three-dimensional load-bearing effect and the clamping between the storey levels.

The production took place in individual segments with up to eight stages. The veneers of the cheeks were first glued to prefabricated molds and then processed with a CNC-controlled milling machine. Then the outer and inner stringers were joined together with the risers and finally the steps were inserted.